At first glance, one doesn’t notice the detail and work put into constructing such a space. The walls forming the kiosk are solely structural yet the materiality of the walls seem to be aesthetic. The columns at the entrance attract ones attention at a physical level but are masking the functionality of the columns. The dark timber looks heavy and obscure but the material itself is very natural and depicts a certain flow and lightness.

Both the walls and columns flow gently out of the ground and gather to form an organic shape. The contrast in forms, shapes and materiality portray a harmony and unanimity between two different cultures.

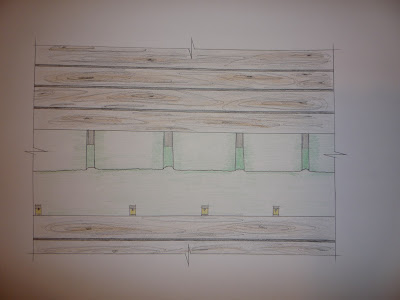

Several layers come together from the structure, the skeletal frame followed by the addition of different materials that unite the structure and the cladding that wraps around the kiosk and hides the various layers.

DSDHA worked along with timber subcontractor Martin Childs who developed a precise technique of charring timber. Together they were able to transform timber into a more durable and resistant form of cladding, which would help with costs and maintenance. The method used was very similar to Yakisugi, a Japanese method highly used in construction in Japan. The technique is mainly based on a cladding finish that uses burnt or charred timber. The technique of attaining a hardened and long lasting charred finish was developed at a commercial level with help from the subcontractors.

The construction process was efficient and fast and was divided into steps that would facilitate the entire procedure. A skeletal steel structure or frame was first built in order to achieve the form of the total space. The pieces of charred timber are shaped into wide panels that are individually fixed to the joists of the steel frame. The burning of the panels was done by Martin Childs who set up an automatically programmed furnace with several gas burners to scorch the totality of the timber used for the finishing. After this step, a high pressure water jet was used to blow off and extricate debris found on the panels. The panels had to be completely dried off, and were taken to the site. Many imperfections are visible on the panels but the lumps and bumps add a textural element to the surface. Everything was prefabricated and taken to the site to put together.

No comments:

Post a Comment